by ticonaeu_oajodn | Jan 26, 2024 | Plastic moulding

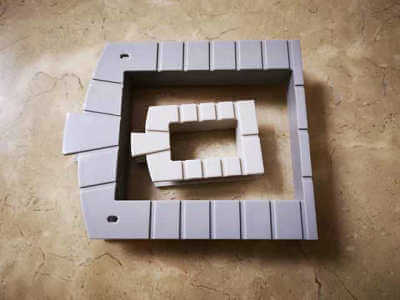

Mastering the Art of Aluminum Die Casting Molds: A Comprehensive Guide In the realm of precision manufacturing, the role of aluminum die casting molds cannot be overstated. GC Precision Die Casting, a renowned player in the industry, has perfected the art of crafting...

by ticonaeu_oajodn | Jan 26, 2024 | Plastic moulding

Unveiling the Essence of Aluminum Die Casting: Choosing a Top-Tier Tooling Manufacturer in China In the realm of precision engineering, aluminum die casting stands out as a formidable method, boasting unparalleled precision and efficiency. At the core of this...

by ticonaeu_oajodn | Jan 11, 2024 | Plastic moulding

Choosing the Best China OEM Die Casting Manufacturer: A Comprehensive Guide I. Introduction to China OEM Die Casting Manufacturer When it comes to sourcing OEM die casting manufacturers, China oem die casting manufacturer have emerged as a global leader in the...

by ticonaeu_oajodn | Jun 17, 2023 | Plastic moulding

Injection Molding Overmolding: Enhancing Product Performance and Design Flexibility Introduction to Injection Molding and Overmolding Injection molding is a widely used manufacturing process that involves injecting molten material into a mold cavity to create a...

by ticonaeu_oajodn | Jun 16, 2023 | Plastic moulding

The Crucial Role of Injection Molding Prototypes in Product Development In today’s competitive manufacturing landscape, injection molding prototypes have emerged as a vital tool in product development. By allowing designers and engineers to test and refine their...

by ticonaeu_oajodn | Jun 12, 2023 | Plastic moulding

Aluminum Die Casting Parts: A Comprehensive Guide to Manufacturing, Advantages, and Applications Introduction: Aluminum die casting parts play a pivotal role in various industries, offering exceptional strength, dimensional accuracy, and cost-effectiveness. This...

by ticonaeu_oajodn | Sep 27, 2022 | high speed hair dryer

The hair is the crowning glory of ever woman. It is one of the best accessories that a woman has that is why it is very important to take care of it and ensure that it always looks good and shiny. This is also the reason why professional hair dryers were created. For...

by ticonaeu_oajodn | Mar 20, 2022 | curling iron, hair styling tools

One of most popular curling irons today is the clipless hair curler, It’s been around long ago and it is still very making waves. Olayer clipless Curling Iron has been ranked high on many Olayer clipless hair curler reviews sites because of its high performance and...

by ticonaeu_oajodn | Feb 19, 2022 | hair styling tools

The Protools Express Ion Smooth Flat Iron plates made by Olayer hair styling tools manufacturer are 1.25 inch wide. It might be the great purchase for you. This flat iron seals the folicle and made the hair super shiny. No matter what kind of hair you have. It works...

by ticonaeu_oajodn | Jan 3, 2022 | best powerful hair dryer

This features on the 1400W best powerful hair dryer is based on yet another powerful blow dryer from the Olayer Chinese best powerful hair dryer company. Olayer hair dryer manufacturer makes a lot of best hair blower but this one seems to be the best high power hair...